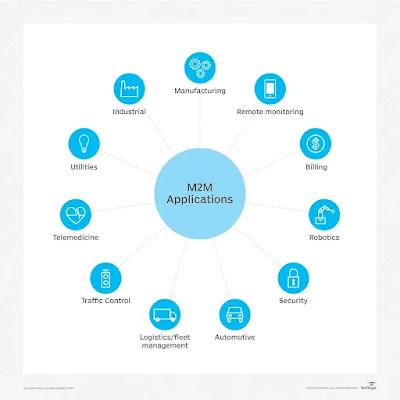

Machine to Machine (M2M) :

In this the association or correspondence happens between machines via mechanizing information/programs. In this machine level guidelines are expected for correspondence. Here correspondence happens without human association. The machines might be either associated through wires or by remote association. A M2M association is a highlight point association between two organization gadgets that aides in sending data utilizing public systems administration advancements like Ethernet and cell organizations. IoT utilizes the essential ideas of M2M and grows by making enormous "cloud" organizations of gadgets that speak with each other through cloud organizing stages.

How M2M works:

The principal motivation behind machine-to-machine innovation is to take advantage of sensor information and communicate it to an organization. Dissimilar to SCADA or other remote checking devices, M2M frameworks frequently utilize public organizations and access strategies - - for instance, cell or Ethernet - - to make it more financially savvy.

The primary parts of a M2M framework incorporate sensors, RFID, a Wi-Fi or cell correspondences interface, and autonomic processing programming customized to assist an organization gadget with interpretting information and decide. These M2M applications interpret the information, which can set off prearranged, computerized activities.

One of the most notable kinds of machine-to-machine correspondence is telemetry, which has been utilized since the early piece of the last 100 years to communicate functional information. Trailblazers in telemetrics first utilized phone lines, and later, radio waves, to communicate execution estimations accumulated from observing instruments in distant areas.

The Web and further developed principles for remote innovation play extended the part of telemetry from unadulterated science, designing and assembling to regular use in items, for example, warming units, electric meters and web associated gadgets, like apparatuses.

Past having the option to remotely screen gear and frameworks, the top advantages of M2M include:

- reduced costs by minimizing equipment maintenance and downtime;

- boosted revenue by revealing new business opportunities for servicing products in the field; and

- improved customer service by proactively monitoring and servicing equipment before it fails or only when it is needed.